Our BuildProcess

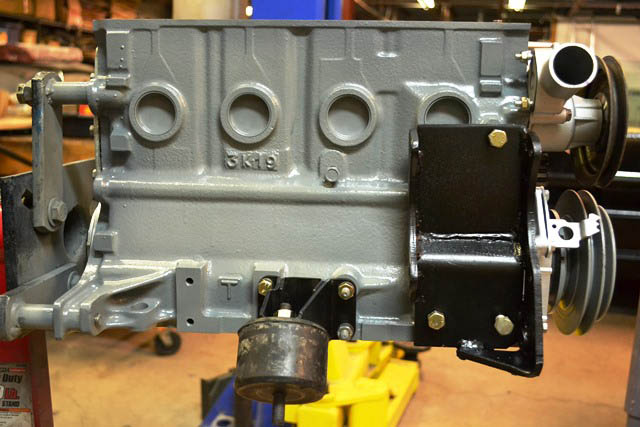

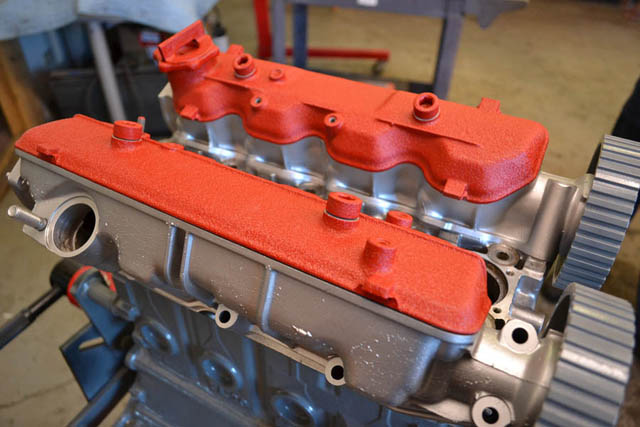

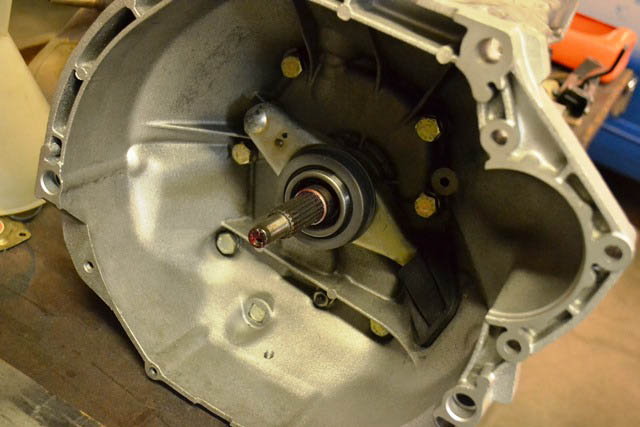

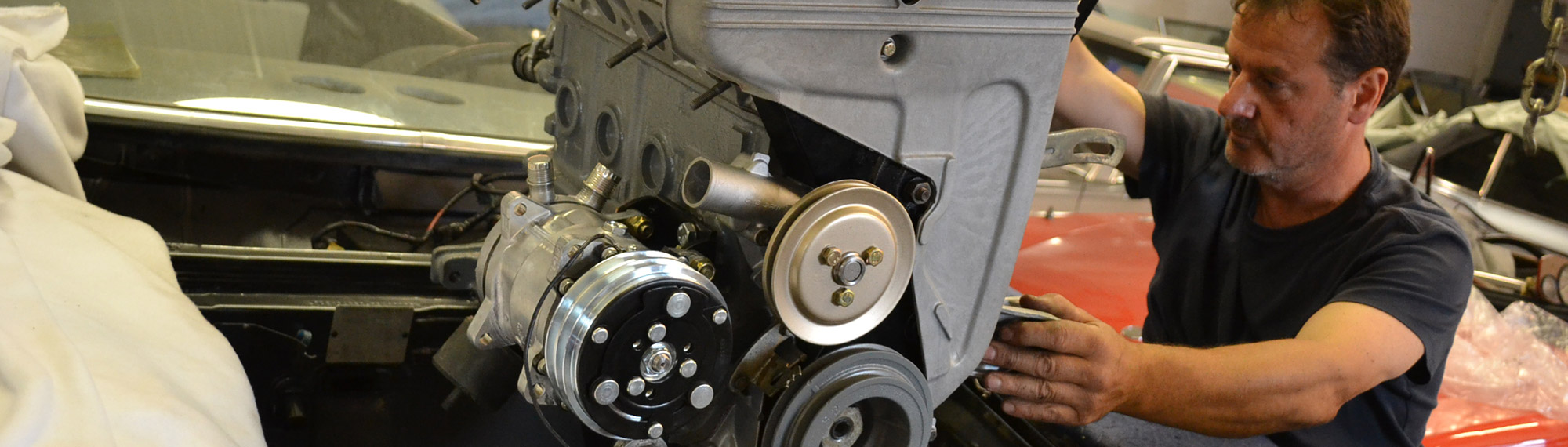

OUR IN-DEPTH RESTORATION PROCESS

Every project begins with selecting a chassis. New metal always replaces any existing corrosion. Stripped to bare metal prior to paint.

Factory insulation is removed. Tubs scrubbed with anti-bacterial solution, then treated w/multiple coasts of rust preventative.

Each interior component is covered in supple leather, hand crafted to the standards of the finest Italian coach builders