Author: Ray Marchica

Yes, it’s Almost Here. The 2024, Intercooled FI 2.0 Turbo

This is not photoshop. Here’s the latest information on the production version of our modern, fuel injected, intercooled turbo. It’s custom dyno-tuned and fresh from our engineering department. Nearly three years in the making. It will be offered in two configurations—a low pressure touring version with an estimated 150 HP, and a 200+ HP high pressure version with internal engine modifications. Cut and paste our YouTube video link of the running system below. Trust us…it’s very cool.

https://www.youtube.com/watch?v=GuvyNQtTtSU

When we first set out to develop a modern replacement for the original Legend Industries turbo build from 81-82, we thought it would be easy to improve upon a forty-year-old design. But we discovered early on that the existing fuel injection would never work properly with a forced induction engine. The old system featured a “closed” computer that could not be tuned for compatibility with a modern turbo. Aside from the obvious requirement of an “open” programmable computer design, many new components were necessary for the design to work. A completely new fuel injection system, wiring harness, sensors and other components were necessary to make management of the turbo fuel system possible. Also needed were costly redesigns of the exhaust manifold and piping. All in all, an enormous undertaking but well worth the effort. Our first production version shown above. Orders will begin shipping in January 2024.

A family Affair

It is truly gratifying when family members share our passion for these lovely cars. This 1980 Fiat Spider had only 12,800 original miles when discovered abandoned in a barn on a cold rainy night 20 years ago. Rescued by Director Rob Baird then sold to his father, the car required only minor repairs and a new set of keys to get back on the road. When first discovered, the Spider literally appeared to be black or dark gray. But once the years of dirt and grime were removed, the Spider revealed pristine original Rosso Cherry paint underneath–with zero signs of rust.

Baird Senior reminisced about his purchase. “I remember when my son first told me about the car. I’d passed on others previously, but with just one look I knew this one was something special. As a young man I’d fancied some British convertibles, like Triumphs and Jaguars. But the Fiat really spoke to me. Rob had the car detailed and a minute later, I was in love.”

Over the past two decades–with assistance from the Roadster team, the Spider has been thoroughly sorted. Under the direct supervision of shop foreman Roberto D’Avola, it’s been meticulously maintained. Recent additions include a flawless set of original 14” Cromodora wheels, restored to perfection and freshly powder coated. The Spider also received a cooling system upgrade, brake refresh and a new custom interior. Rob’s father enjoys his stunning Fiat Spider daily during the lovely Chicago Summers. Today the car still has only 28,000 original miles and looks like it just drove off the showroom floor. Pictured above is Rob, his father and some of our Roadster team. Truly a family affair.

New FI System to Benefit Non-Turbo Customers

Those watching our blog know that the stock Bosch fuel injection system is incompatible with our advanced turbo design. This required a complete re-think of how fuel management in general can work in a Spider. Once the turbo system plumbing was finalized, our interests turned to developing a workable injection design that could not only solve the turbo challenges but potentially be used with non-turbocharged cars as well.

According to Director of Operations Rob Baird, the solution is near. “We realized early on that the turbo design would be highly complex and require advanced engineering and tuning. During the process we discovered an additional benefit for those who did not wish to add forced induction to their Spiders. The new fuel injection system has the potential to improve performance and reliability all on its own merits”. Baird added further that early returns on the design have been very positive, as the new system allows for a smoother running engine that feels significantly more modern. Production version of the 2.0 FI turbo is shown above, being installed into our first customer project. The project is getting close to completion with Dyno testing scheduled for late September.

Still Waiting—Production Wrecked by No Racks

A sad scene at Roadster Salon this summer with many phases of production at a standstill. While still able to build drive lines, suspension and interiors—final assembly which includes the installation of engines and interiors has ground to a halt. The initial shipment of steering racks received in April could not be installed due to a manufacturing error from our new supplier in Europe. Additional refinements in the design were required prior to installation. The racks were shipped back to Germany for additional modifications that could not be handled state-side.

There is light at the end of the tunnel however, as the newly fabricated components are due back here in the US toward the end of July—which means arrival in Chicago mid-August after clearing customs. We apologize to our many customers who expected to see their projects completed earlier this Spring and Summer. According to production assistant Robert Rak “We have over a dozen chassis all in the same stage of readiness. Once the steering systems can be installed, things will start hopping.”

Turbo Team Makes Major Progress

Pictured above is Roadster Salon’s turbo test mule. It may not look like much progress, but the turbo plumbing, intercooler and exhaust design has been installed. We are happy to report everything fits and we can now move on to the next steps which will include development and installation of our new proprietary fuel injection system. The design will incorporate a programmable fuel management computer and modern high-flow injectors. We aren’t prepared to quote horsepower goals or pricing. But since the system can by dyno tuned and has the potential for high boost pressures—a theoretical 200HP is a realistic goal. If those numbers are achieved, more chassis development will need to accompany the dramatic increase in power. Keep your eyes on this space for more details. Porsche Boxster owners beware. You are in for some serious “indigestione”

The Best Laid Plans…

There is no easy way to say this, but our best laid plans to increase production to meet demand this summer driving season are off to a rocky start. This Spring, several of our best suppliers have reported stocking issues with numerous categories of components. These parts include alloy wheels, leather material, steering racks, and certain drive line items. Obviously, all are critical to our build process. While nothing new in post COVID times, we were caught unprepared and forced to locate other supply lines to fill in the gaps. We have only been partially successful finding alternatives to many items.

According to Director of Operations Rob Baird, “in spite of our efforts to plan ahead, these shortages have put our summer ramp-up process in serious jeopardy. The past few years have been challenging—as we’ve watched friends in our industry continue to struggle in this unpredictable business climate. It is gratifying to report that Roadster currently has several years of back orders. At face value this is a wonderful problem to have. But in reality, the daily stress of meeting customer expectations set prior to the pandemic can be daunting to say the least”. Watch this space and email thread for more updates.

Steering Rack Disaster

It may not look like much, but the photo above shows a portion of our proprietary custom rack and pinion steering upgrade. Back in December, we ordered our usual allocation of steering racks from our supplier—only to find that the unit had been discontinued without any warning or notice. Their excuse was lack of demand after COVID.

When you consider that our entire steering system design has revolved around this product since 2017, it was quite a blow. To the uninformed, it’s hard to appreciate the scope of this problem. Put simply, you can’t drive a car you can’t steer. Since the rack is connected to the cross member, you cannot install your engine without it. Further, interior installations must also be put on hold, as you are unable to weld beneath the car with anything combustible above it. This means production has ground to a halt. Luckily, we found a supplier in Germany who is willing to work with our specifications and re-supply our team in a timely fashion. Watch this space as the situation develops.

Roadster Announces First Proprietary Turbo System

Your eyes do not deceive you. After several years of conversation and pre-development, Roadster Salon’s engineers and subs have committed to building a contemporary turbo system for the 2.0 fuel injected spider. The modern turbo idea was first entertained in the early 2000’s by Roadster’s sales team led by Ray’s father prior to his passing. The original Legend industries turbo was a bolt on disaster, designed to take advantage of the “turbo craze” in the early 1980’s. Only 700 were built. They offered cool body graphics, a neat boost gauge in dash, and enough performance to notice a gentle push forward in second and third gear. If all elements aligned, you enjoyed a modest 20% increase in power until the system went south. Unfortunately, this usually happened after a scant 30K miles—less if you drove aggressively.

Our concept won’t come cheaply, as the design isn’t compatible with the stock fuel injection or the original computers. But Roadster Salon’s new contemporary turbo has tremendous upside. Watch this space as the project develops.

Roadster Salon Increases Production Capabilities for 2023

Roadster Salon’s pandemic rebound continues into 2023. After two years of snail-paced productivity hampered by parts shortages, vendor closures and staffing challenges, Roadster is poised for a significant rebound this year. Roadster Salon is implementing number of major changes including staff additions, sub-contracted engineering, and more.

“Prior to the pandemic, Roadster Salon’s business model allowed for steady progress on multiple projects simultaneously. But it has been more than two years since we’ve seen that level of productivity,” said Rob Baird Director of Operations. “The number of projects under Roadster Salon management has literally tripled since 2019, and we have been unable to keep up with demand.” According to Baird, to enhance overall efficiency without compromising quality, major changes were necessary. “We are now directly importing a number of parts rather then relying solely on Domestic suppliers. Roadster is securing our own body shop facility to do our projects exclusively. Body/Paint work has been a huge impediment to our overall ability to finish cars. Our volume has allowed us some influence on timelines, but it isn’t the same as having 100% control,” said Baird.

Roadster Salon is also making changes to their supervisory structure at the shop, integrating additional technicians and fashioning more efficient workspace. “We are creating an environment with more emphasis on team building and cooperation. Roles will now be more interchangeable. Previously we focused on performing tasks that were tailored to individual skill sets. It made everything take longer than necessary. One person off work made projects grind to a halt. This is going to return big dividends in the future”, said Baird.

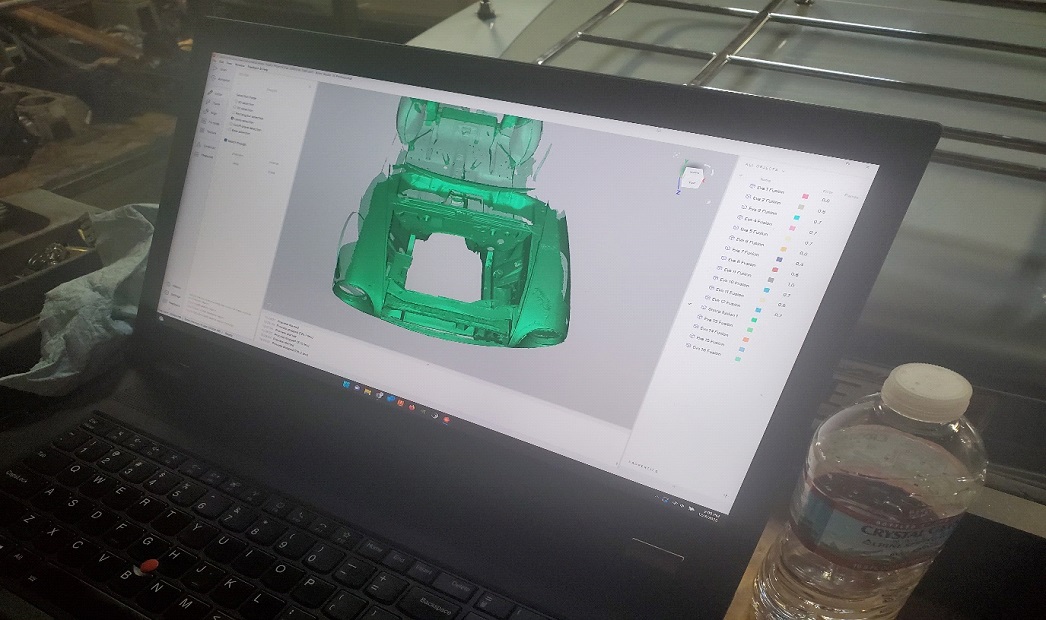

Spider Engineering Leaps into the Digital Age

As our loyal followers are aware, aftermarket development of the Fiat Spider has been moribund since the 1990’s. Roadster Salon has been the leading creative source for engineering improvements of the original spider design. We’ve stood alone, championing upgrades intended to enhance the Spider’s driving experience and overall safety.

For years, our engineers took an old school approach to design and development. This involved literally “drawing up changes on a napkin” and countless hours of trial and error during fabrication. It would take months or even years to bring concepts to a prototype stage. It was a well-meaning effort, but a costly way to make even minor improvements in performance, road manners and reliability.

Roadster Salon has now fully advanced into the digital age. Director Rob Baird said, “While we still originate our own design concepts in house, we are contracting with an outside engineering firm to computerize them so we can work exclusively in the digital domain. This Fall, our engineering firm spent several days doing complete digital scans of the spider chassis and major components. They used sophisticated laser interpolation and tens of thousands of dollars in modeling software to create a full digital picture of the Spider,” said Baird.

“We now have precise measurements of every critical part of the original car. Modeling of newly designed components can now be tested within a computerized environment for precise fitment. Changes and updates are made easily. Strength and durability of new components can be measured and tested theoretically without ever installing them in a Spider. Specifications for new parts can be quickly finalized and put into production. It’s a game changer.”

The coming year looks to be the most creative period in Roadster Salon’s history. New designs include high performance crate engines/transmissions, next generation chassis upgrades, an improved turbo system and our latest EV design. Watch this space as these new products come to market.